Bridge Saws

TFM

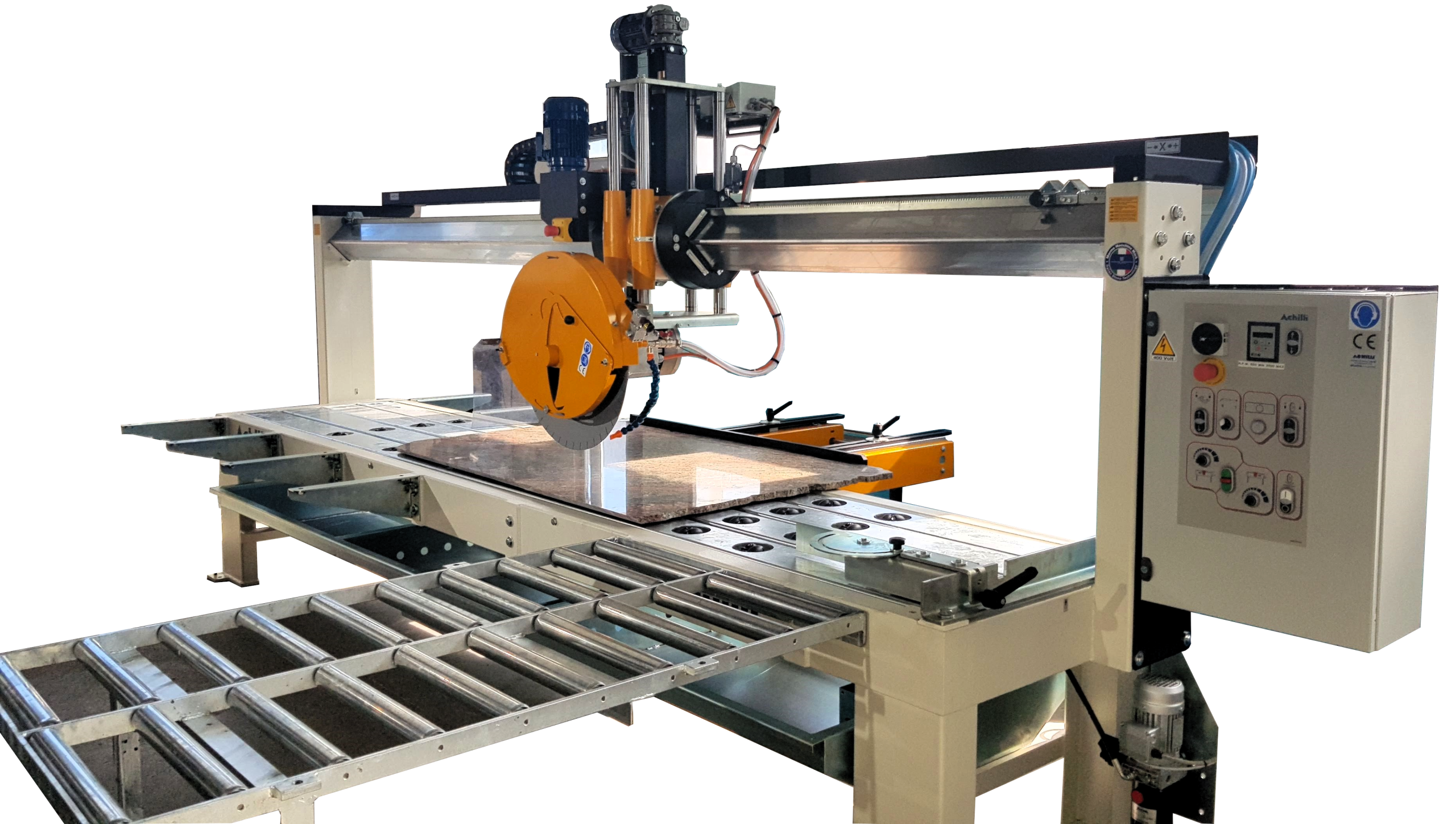

Mini bridge saw TFM

Stone saw with fixed bridge for stone, quartz and ceramic slabs

Stone saw with fixed bridge for stone, quartz and ceramic slabs Monoblock saw with fixed bridge for stone and sintered material slabs equipped with a compressed, rectified and chromed “active beam” guaranteeing the utmost accuracy. The worktable extensions widen the worktable facilitating the positioning of large slabs and the head feed is motorized with variable speed adjustment in both directions.

ADVANTAGES

TFM is an extremely sturdy bridge saw, suitable to cut thick stone slabs:

- Customizable according to customer requirements;

- Equipped with a special design beam providing the utmost accuracy;

- Optional PLC control unit for step-cut programming;

- Extremely accurate cutting on stone, ceramic, quartz and sintered materials;

- Motorized head motion with variable speed on X axis in both directions.

TECHNICAL DETAILS

| 1 | 2 |

|---|---|

| X axis travel | 3100mm (10’2”) or 3500mm (11’5”) |

| Z axis travel | 380 mm |

| Worktable dimensions | 3695×900 mm |

| Diamond blade diameter | 300-400 mm (12"-16") or 400-625 mm (16"-25") |

| Blade bore size | 50 mm |

| Motor power | 7.5kW = 10HP / 11kW = 15 HP (3ph.) |

| Main motor rotation speed | 1400 rpm 50Hz – 1700 rpm 60Hz |

| Standard voltage/ frequency | 400V-50/60Hz / 230V-60Hz 3ph. |

STRUCTURE

Steel frame, sandblasted and ceramic coated (hot-dip galvanized upon request).

HEAD TILT

Manual head tilt from 90° to 45° for inclined cuts

WORKTABLE

Worktable made of galvanized steel rails.

CUTTING DEPTH ADJUSTMENT

Motorized working depth adjustment along Z-axis by geared motor.

HEAD MOTION

Motorized head motion with variable speed on X-axis, in both directions and motorized working depth adjustment along Z-axis by geared motor.

EXTENSIONS AND SIDE STOP INCLUDED

The worktable is equipped with worktable extensions and a side stop for easy movement of large slabs

ACCESSORIES

DEVICE FOR PARALLEL CUTS

Machine can be equipped with a special device that, controls the movement of the side stop, and facilitates the execution of parallel cuts. The side stop runs parallel to the cutting line by means of a special hand wheel.

VARIABLE SPEED

Manually adjust the speed of the blade depending on the worked material.

DIGITAL DEVICE FOR PARALLEL CUTS

The machine can be supplied with a sidestop device equipped with a mechanism that facilitates the execution of parallel cuts. By means of a handwheel, the side stop is made to slide parallel to the cutting line, so as to avoid repeated attempts of manual measurement. The displacement is displayed by means of a digital position indicator equipped with an LCD display, which reads the position by means of a head on a decimal magnetic strip. The position indicator can be reset at any point and it is possible to program it to keep in memory the thickness of 3 different discs. If properly selected the thicknesses will be automatically added to the measurement to be made

CONTROL PLC

PLC control unit for step-cut programming.

WORKTABLE WITH POP-UP ROLLERS

Pop-up rollers manual or motorized to facilitate slab loading and positioning: roller table with omni-directional rollers

SIDE EXTENSION TABLES WITH ROLLERS

Side extension tables equipped with rollers to facilitate slab movement. Dimensions: 60x34in. (1510x865mm)

LASER

Laser alignment device mounted on the head shows the blade’s cutting line.

WATER TANK

Water tank with built in recycling pump for blade cooling during cutting.

SIDE TABLE

For large slabs, this machine can be equipped with 2 side extension tables. Dimensions: 60x34in. (1510x865mm)