Bridge Saws

AFR A

Motorized bench saw AFR-A

Stone cutting saw with variable speed for stone and ceramic

Compact, essential and sturdy bench saw with fixed bridge; the bridge tilts and the water tank with built-in recycling pump makes it the perfect saw for the stone fabricator. It is equipped with 1 or 2 side extension tables to enlarge the working surface and facilitate the positioning of the slabs.

ADVANTAGES

Fully equipped and motorized saw AFR-A suitable for small and large stone fabricating shops

- Available with several useful cuts, according to customer requirements;

- Maximum cutting precision guaranteed by a special beam design;

- Suitable for ceramic and sintered material slabs

- Available with multiple blades for processing anti-slip grooves;

- Motorized head feed with variable speed in both directions.

TECHNICAL DETAILS

| AFR-A | AFR-A HT | |

|---|---|---|

| AFR-A | AFR-A HT | |

| Useful cut | 1000–1500–2000-2500–3000–3300-3500 mm (3’3” - 4’11” – 6’6” – 8’2” – 9’10” – 10’10” – 11”5’) | 1000–1500–2000-2500–3000–3300-3500 mm (3’3” - 4’11” – 6’6” – 8’2” – 9’10” – 10’10” – 11”5’) |

| Diamond blade diameter | 250-300-350 mm (10”–12”–14”) | 400-450-500 mm (16”–18”–20”) |

| Blade bore size | 25.4 mm (1") | 25.4 mm (1") |

| Motor power | 5kW = 6.5HP (3ph.) | 4kW = 5.5HP (3ph.) |

| Main motor rotation speed | 2800 rpm a 50Hz – 3400 rpm a 60Hz | 1400 rpm a 50Hz – 1700 rpm a 60Hz |

| Standard voltage/ frequency | 400V-50/60Hz /230V-60Hz 3ph. | 400V-50/60Hz /230V-60Hz 3ph. |

HEAD FEED

Motorized head feed with variable speed in both directions.

BRIDGE TILT

Manual bridge tilt for cutting from 90 to 45 degrees

WORKTABLE

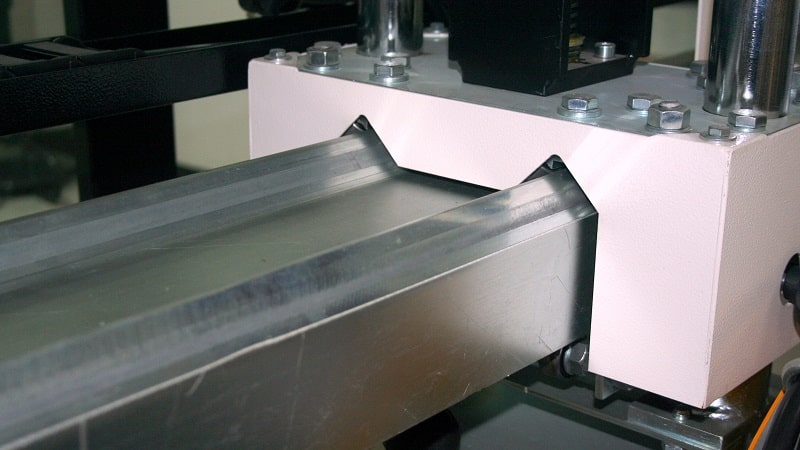

Worktable made of galvanized steel rails.

CUTTING DEPTH ADJUSTMENT

Motorized working depth adjustment along the Z-axis by geared motor.

MULTIPLE BLADES

Available with multiple blades for processing anti-slip grooves.

ACCESSORIES

DEVICE FOR PARALLEL CUTS

Machine can be equipped with a special device that, controlling the movement of the side stop, facilitates the execution of parallel cuts. The side stop runs parallel to the cutting line by means of a special hand wheel.

HT VERSION

Highest and robust increased version with blade guard for disc Ø 15.75-19.5in. (400-500mm) and 3phase motor, 5.5hp (4kW)

ADJUSTABLE ANGLE SQUARE

Adjustable angle square for maximum cutting precision, length 600mm.

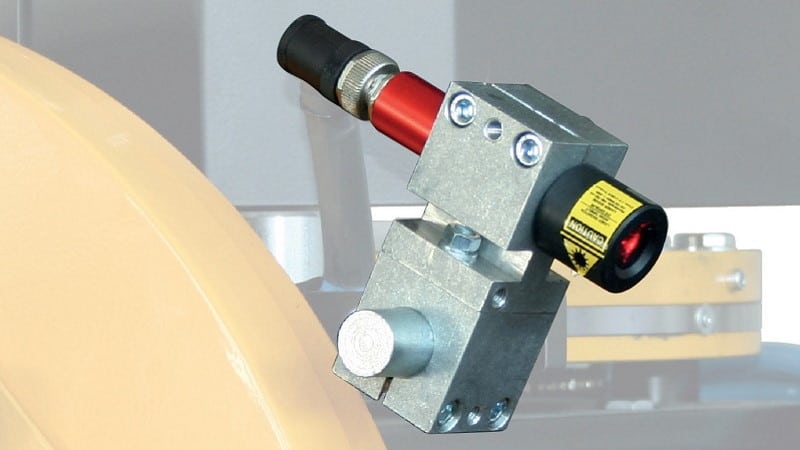

LASER

Laser alignment device mounted on the head shows the blade’s cutting line.

SIDE TABLES WITH ROLLERS

Side extension table equipped with rollers to facilitate slab movement. Dimensions: 40x18in (1000x458mm)

GALVANIZED WATER TANK

Galvanized and painted water tank, for the maximum rust resistance.