Floor Machine

LM30-VE

Universal 1-phase floor grinder LM30-VE universal floor grinding and polishing machine for stone floors

Universal single phase floor grinding and polishing machine for stone floors. Equipped with variable speed this floor grinder is perfect to work marble, terrazzo, concrete, granite and any kind of stone

ADVANTAGES

The LM30-VE is our best selling floor grinder, the most popular model for professional floor grinder operators, both in Italy and across the globe

- Three-phase motor driven by frequency inverter thus improving machine output.

- Toggle between four different speeds to choose the best option for any floor.

- Machine level adjustment by eccentric wheel axis.

- Easy grip handles and pivoting wheels for effortless movements.

TECHNICAL DETAILS

| TITLE | DETAIL |

|---|---|

| Power | 2.2Kw – 3HP / 3kW – 4HP |

| Voltage | 230V (monofase) |

| Motor rpm | Elantra |

| Honda | 300 mm |

| Plate rpm and peripheral speed | 1 - 150 rpm – 141 m/min 2 - 351 rpm – 330 m/min 3 - 439 rpm – 413 m/min 4 - 527 rpm – 496 m/min |

| Water tank capacity | 26 l |

| Size | 500x995x1300mm |

| Net weight | 100 kg |

| Gross weight | 120 kg |

Sturdy and compact structure. Aluminum tank with epoxy powder finish.

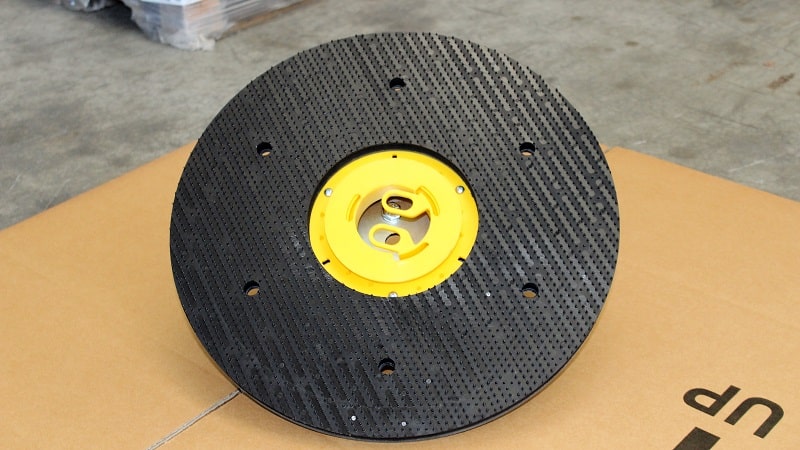

Three-phase motor driven by a frequency inverter to improve machine output. Available with 2.2kW-3HP motor or with a powerful motor 3kW-4HP. ABRASIVE HOLDING PLATE Available with Prismatic, Frankfurt or Comma type abrasive holding plate, at customer’s choice.

Available with Prismatic, Frankfurt or Comma type abrasive holding plate, at customer’s choice.

ACCESSORIES

ACCESSORIES PROVIDED

Abrasive holding plate 11.8in. (Ø300mm), shock absorbing springs (outer and inner type) plastic splash guard ring, squeegee and set of servicing wrenches.

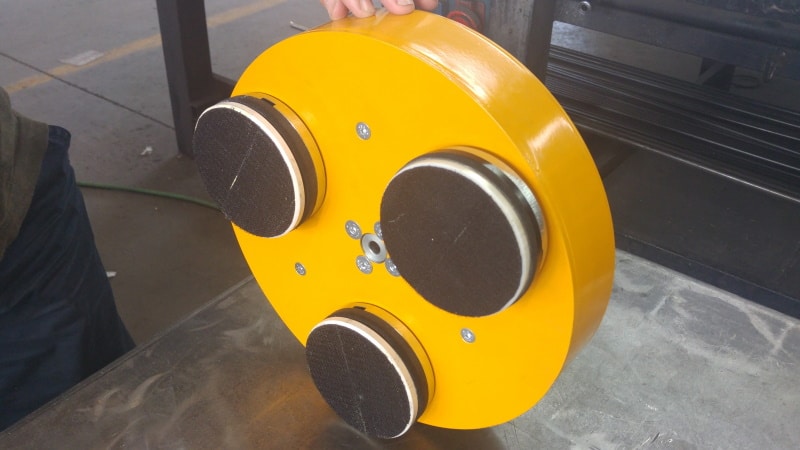

PLANETARY HEAD

Planetary head 11.8in. diam. (300mm) complete with flange and tool holders to easily work granite and hard stones and to optimize processing on all surfaces.

BUSH-HAMMERING PLATE

Optional accessory for surface bush hammering, available with different grits.

SINGLE HEAD DRIVING PLATE

Optional single head driving plate 17in. diam. (430mm), for using single head machine tooling. The inverter lower speed is programmed for the use of single head machine pads and accessories.

EXTRA WEIGHT

Extra weight to increase usable grinding pressure.